Overview

Market Center

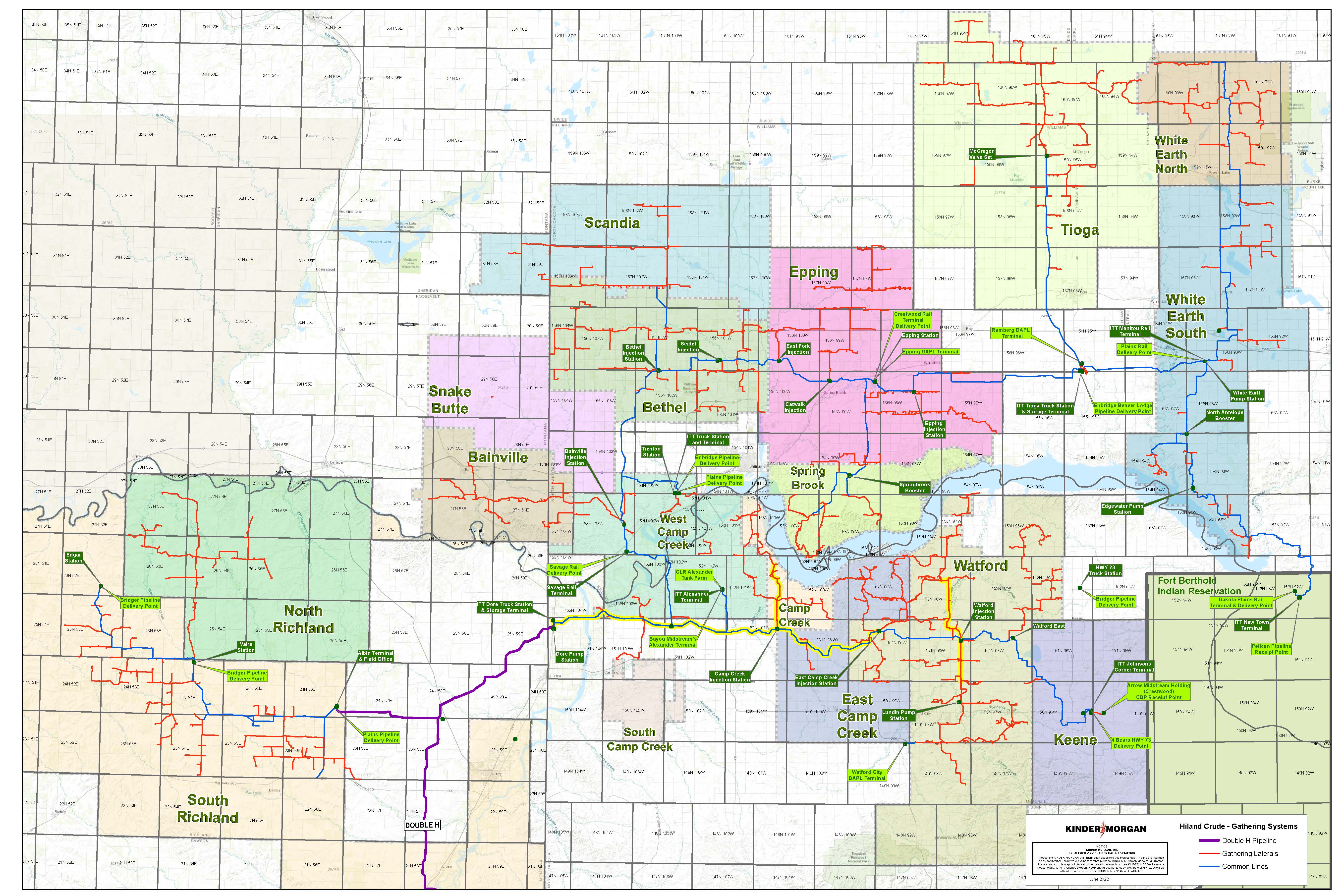

Hiland’s Market Center Gathering System serves producers and marketers in the Williston Basin. The system spans the major counties of McKenzie, Mountrail, Williams in North Dakota and N.E. Richland County in Montana located in the Bakken Shale providing crude oil gathering and transportation services. Superior market optionality is provided to producers and marketers thru interconnects with all the major takeaway pipeline systems including Enbridge ND, Dakota Access (Gulf Coast mkt), Double H (Guernsey mkt), and Double H/Pony Express (Cushing Mkt) as well as 3 rail terminals (Crestwood Epping formerly COLT), Savage, and BioUrja (New Town) providing rail service to the East, West, and Gulf Coast markets. The system consists of 4-inch thru 12-inch pipe and has the capability to move over 300,000 barrels per day of a fungible grade of Bakken Crude Oil. The system has truck unloading terminals at Dore Station, Johnson’s Corner, and Alexander.

Tioga

Hiland’s, Tioga Gathering System serves producers in Burke and Divide County, North Dakota. The system interconnects with Dakota Access and Enbridge N.D. pipelines as well as with Hiland’s Market Center System providing excellent market optionality for producers and marketers. The system operates with a fungible grade of Bakken Crude Oil and interconnects with ITT’s Tioga Terminal providing access to truck unloading, Dakota Access and Enbridge Pipelines as well as the Hiland Market Center System providing superior market optionality for producers and marketers.

Richland County

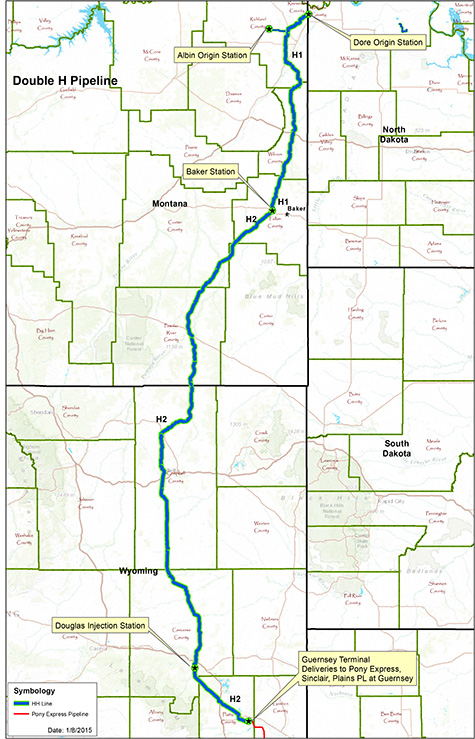

Hiland’s Richland County Gathering System serves producers and marketers in Richland County located in Eastern Montana. The system interconnects with Double H Pipeline providing access to the Guernsey, Wyoming and Cushing, Oklahoma markets. The system’s Albin Terminal provides truck unloading and blending services. In addition the system interconnects with Bridger Pipeline at Richie and Viara as well as Plains Pipeline at Lone Tree.

Badlands Crude Gathering System

Hiland’s Badlands Gathering System serves production in Southwestern North Dakota. The system interconnects with Double H and Butte Pipeline at Baker, Montana.

Terminals and Truck Stations

Independent Trading and Transportation LLC owns and operates crude oil terminals located on the Hiland’s Market Center and Tioga Gathering Systems in North Dakota and on Hiland’s Double H System at Guernsey, Wyoming. ITT also engages in crude oil purchasing and marketing in the Bakken and Powder River areas.

Resources

.jpg?lang=en-US)

Terminal Location:

Terminal Location: Terminal Location:

Terminal Location: